Load Cell Calibration in india

- Home

- Load Cell Calibration

Load Cell Calibration in India: Achieving Precision and Reliability

Load cell calibration is an essential process for ensuring measurement accuracy and reliability in a variety of industries, including manufacturing, aerospace, automotive, and healthcare. Precision measurement tools are in high demand in India, thanks to industrial expansion and stricter quality control standards.

What Does "Calibration" Mean?

The process of comparing a sensor’s measurement results to a calibration standard in order to make the necessary corrections to minimize deviations or errors is known as calibration.

Calibration services are essential in many industries, including industrial processing and manufacturing, as they help guarantee that instruments and systems provide accurate measurements and consistent results, enable dependable data analysis, precise measurements, and adherence to industry standards.

Maintaining accuracy and consistency in equipment and devices requires frequent and regular calibrations at regular intervals.

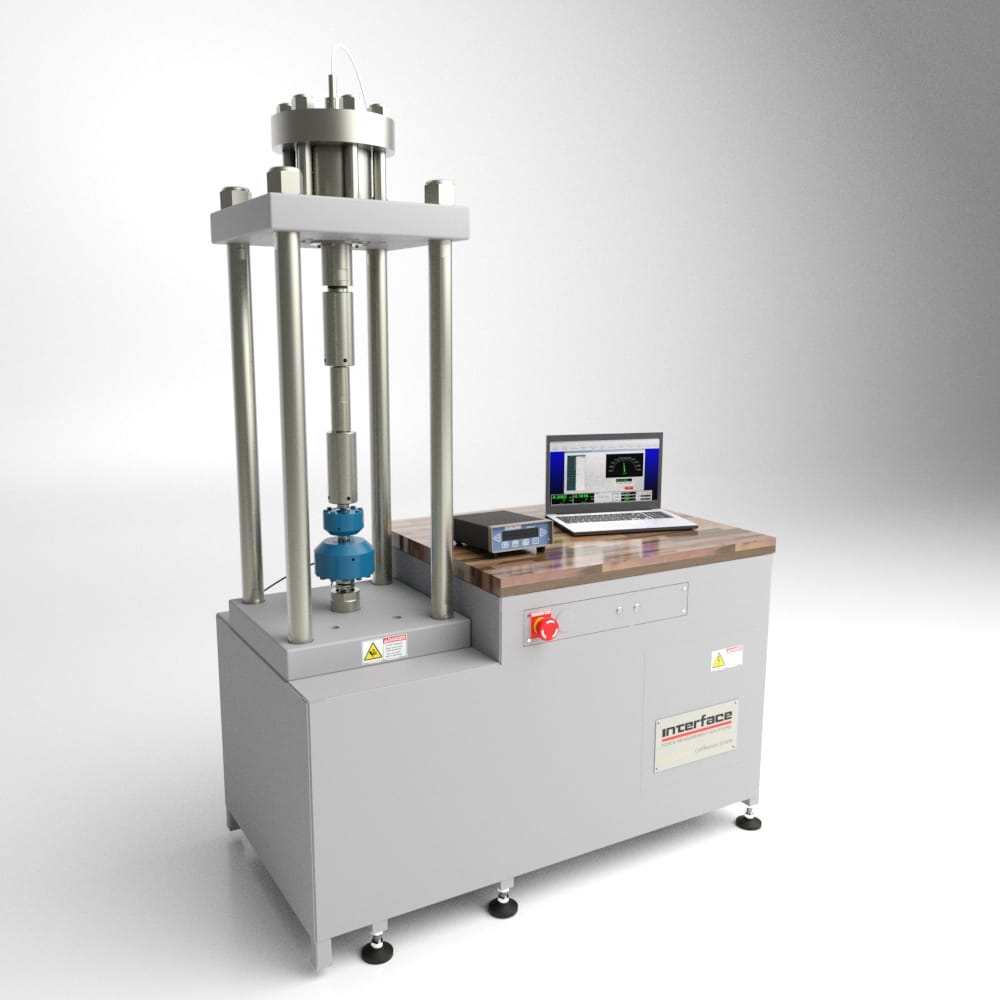

What is the calibration of a load cell?

When measuring instruments are calibrated, their readings are compared to a known-to-be-accurate device to ensure that they are operating by standards or specifications.This typically entails applying a known load up to the rated capacity of the unit being tested, either using masses or a force-generating apparatus equipped with a reference load cell, in the case of load cells and weighing instruments.

How come my load cell needs to be calibrated?

Reliable, repeatable measurements within acceptable accuracy tolerances are guaranteed by routine calibration of load cells.A load cell is made up of several interdependent parts. The spring element, or load cell body, deflects in response to an applied load.-the signal conditioner (amplifier/display), which increases output in proportion to resistance change; -the bonded strain gauge, which modifies resistance in proportion to spring element deflectionAny component may experience gradual changes in response over time as a result of usage intensity, external factors, and loading circumstances, especially in the case of impact loads, vibration, or overload.

How frequently should my load cell be calibrated?

To guarantee the accuracy of measurements and safe operation, we advise having load cells inspected and calibrated once a year.The actual timeline may not be specified, even though periodic calibration may be required by legislation, a quality management system, or compliance with standards and regulations about particular industrial processes. In the end, the decision belongs to the owner of the equipment and will be impacted by how vital and frequently they use it.

Calibration Methods

Calibration for dead weight

Deadweight calibration involves evenly loading the vessel to 10% of its live load capacity with standard weights. The weight indication is documented, and the weights are removed. The process material is then added to the vessel until the weight indicator reads 10% of the calibration weights’ weight. Now that the vessel has been refilled with calibration weights, the reading—which is currently at 20%—is recorded. These steps are repeated until the capacity is at 100%.

Calibration of Liveweight

A new and faster method known as “live weight calibration” involves using pre-weighted individuals as calibration weights rather than calibrated dummy weights. It is the same process as deadweight calibration. This method should not be used if there is a possibility of injury.

Material transfer

The material transfer method of load cell calibration uses a different scale to verify weight. The accuracy of the reference scale is the method’s limiting factor, and material loss during transfer may cause some errors.

Master Cells

A master cell can be used for calibration as long as it is at least three times more accurate than the calibrated system. The calibration process for load cells entails loading incrementally and evaluating the output signals of the master load cell and calibrated weighbridge at each stage. The user selects how many divisions to use and whether to apply force with a servo motor or a hydraulic system.

Conclusion

Load cell calibration is an important aspect of maintaining precision in many industries throughout India. Businesses can ensure regulatory compliance, improve product quality, and increase operational efficiency by working with accredited and experienced calibration service providers. Regular calibration not only ensures measurement accuracy, but also contributes to the overall reliability and success of the country’s industrial operations.